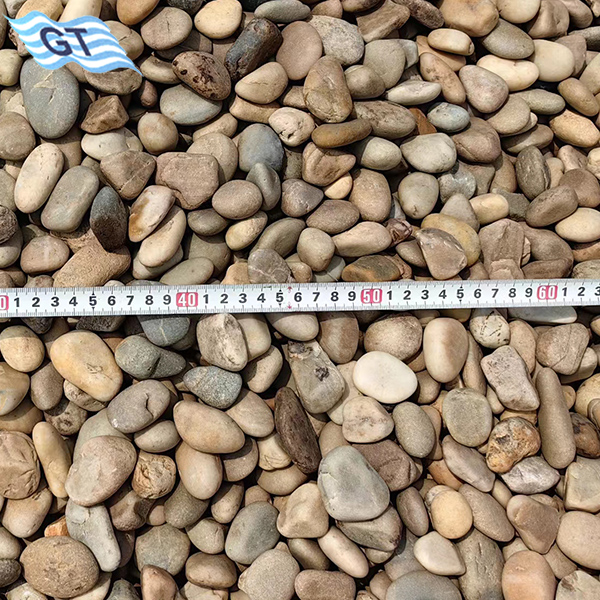

Our enterprise constructs, buys, owns, and manages hydroelectric complexes, wind turbines, solar energy plants, and energy storage tanks. process of flint pebbles,

ceramic insulator, Steel ball, Silica lining bricks, Our team is constantly researching and developing innovative solutions to produce green energy more safely, efficiently, and sustainably., Cannes, Myanmar, Hyderabad, Our mountainous expertise in the realm of metallurgy, ore, and energy has yielded prosperous outcomes both at home and abroad. Customized suitable bricks according to the ball mill sizeSilex lining bricks---provide two types cutting bricks,Manual

High purity alumina spherical powder is a powder material with excellent mechanical properties and corrosion resistance,

Daily ceramics are items that are often used in our daily lives. They are strong and durable, beautiful and practical, e

At the beginning of July, our Dalian Gaoteng finish processing of two sets silex lining bricks for our Japanese custom

*文章标题 *文章简介 How to improve the grinding efficiency of ceramic balls. "The sand mill converts chemical energy into crushing energy for raw materials through grinding. Its basic principle is to disperse and pulverize raw material particles by friction, cutting and impact in the middle of grinding. The relative density, strength, particle size and filling rate of the grinding directly affect the grinding efficiency of the sand mill. 1. Relative density Relative density should be expressed in term

It is best to use ceramic lining bricks for the inner lining of the ball mill. The appearance of the ceramic lining bricks of the ball mill is fine and white, and the two lining bricks are connected by snap buttons to ensure the connection strength. Its main component is high-quality alumina, which has high whiteness and has no adverse effect on the quality of the ground material. There are five types of ceramic lining bricks for ball mills, namely straight bricks, inclined bricks, straight half

Alumina ceramic balls will be used by more and more ceramic manufacturers. According to different alumina content, they can be divided into medium aluminum balls, medium and high alumina balls and high alumina balls. Generally, we classify 60%-65% alumina content as Medium aluminum balls, those with 75%-80% alumina content are called medium and high aluminum balls, and those with more than 90% alumina content are high aluminum balls.

*文章标题 *文章简介 How to improve the grinding efficiency of ceramic balls. "The sand mill converts chemical energy into crushing energy for raw materials through grinding. Its basic principle is to disperse and pulverize raw material particles by friction, cutting and impact in the middle of grinding. The relative density, strength, particle size and filling rate of the grinding directly affect the grinding efficiency of the sand mill. 1. Relative density Relative density should be expressed in term

English

English