We are a high-tech organization dedicated to science innovation, product innovation and administration innovation in Aluminium Ceramic Grinding,

ceramic plates, silex bricks, silex blocks, As a predominant producer in related businesses in China, we center of attention on customising special types and models. We assume to hear from you soon., Madagascar, Jeddah, Washington, Our items earned a distinguished recognition thanks to their dependable operation, sensible fee, and superior after-sale aid. Dalian Gaoteng not only provides regular size of silica pebbles, but also provides customized services according to cust

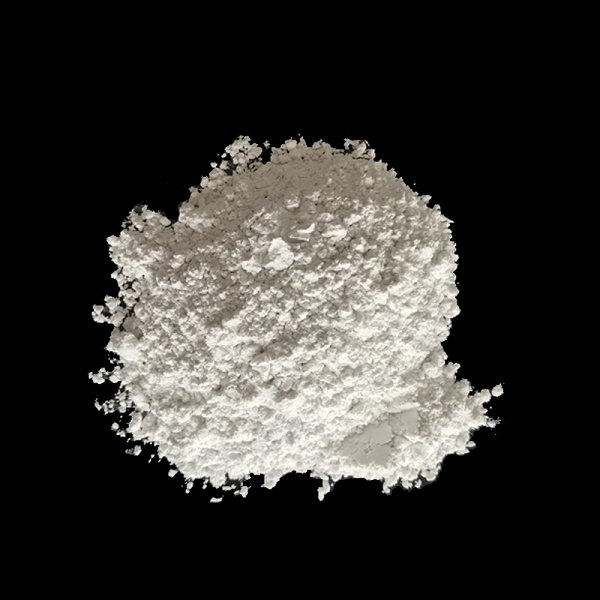

Fumitec corporation is supplier of High Purity Quartz Powder covering the Semiconductor needs of Japan, Korea, Thailand,

The Precautions before installation of ball mill lining brick1.The ball mill should be installed on the base as far as p

Recently, Dalian Gaoteng successfully exported 10 containers of high-quality white silica sand to Australia. This batch

Wear-resistant ceramic lining is a material mainly made of alumina (AL2O3), supplemented with other ingredients, and sintered at a high temperature of 1700°C. It is widely used in thermal power, steel, smelting, machinery, coal, mining, chemical industry, Different types of products can be selected according to different needs for coal conveying, material conveying systems, pulverizing systems, ash discharge, dust removal systems and other mechanical equipment with heavy wear in cement, port and

*文章标题 *文章简介 How to improve the grinding efficiency of ceramic balls. "The sand mill converts chemical energy into crushing energy for raw materials through grinding. Its basic principle is to disperse and pulverize raw material particles by friction, cutting and impact in the middle of grinding. The relative density, strength, particle size and filling rate of the grinding directly affect the grinding efficiency of the sand mill. 1. Relative density Relative density should be expressed in term

It is best to use ceramic lining bricks for the inner lining of the ball mill. The appearance of the ceramic lining bricks of the ball mill is fine and white, and the two lining bricks are connected by snap buttons to ensure the connection strength. Its main component is high-quality alumina, which has high whiteness and has no adverse effect on the quality of the ground material. There are five types of ceramic lining bricks for ball mills, namely straight bricks, inclined bricks, straight half

*文章标题 *文章简介 How to improve the grinding efficiency of ceramic balls. "The sand mill converts chemical energy into crushing energy for raw materials through grinding. Its basic principle is to disperse and pulverize raw material particles by friction, cutting and impact in the middle of grinding. The relative density, strength, particle size and filling rate of the grinding directly affect the grinding efficiency of the sand mill. 1. Relative density Relative density should be expressed in term

English

English