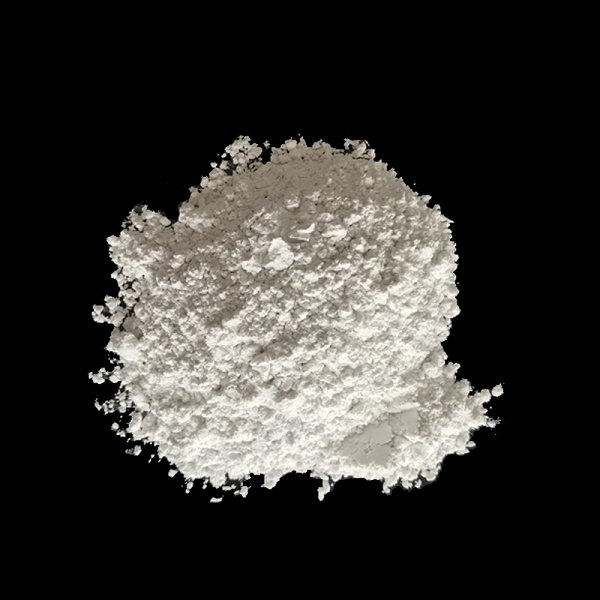

We have belief in a outstanding world the place luxurious renewable energy fashions healthful human beings and fosters mutual enrichment. flint Pebbles for White Cement Industry,

wear resistant alumina balls, silex lining bricks for ball mill, ZTA balls, Our competent, accountable and well-trained crew is prepared to advance really useful and jointly wonderful enterprise associations with you soon. Please do not hesitate to contact us for greater information., Chicago, Madras, Somalia, Our products acquired a high esteem thanks to their dependable action, moderate rate, and exemplary after-sale support. Dalian Gaoteng International Logistics Company already has 25 years of history. We can support One-stop container import

Dalian Gaoteng has been in the field of grinding media for more than 25 years. High-quality ore, strict quality control,

Mining grinding equipment mainly includes the following types:Rod mill. This equipment adopts advanced controllable disc

Optical glassCordierite has good optical properties, including high transparency, low scattering, and excellent refract

*文章标题 *文章简介 How to improve the grinding efficiency of ceramic balls. "The sand mill converts chemical energy into crushing energy for raw materials through grinding. Its basic principle is to disperse and pulverize raw material particles by friction, cutting and impact in the middle of grinding. The relative density, strength, particle size and filling rate of the grinding directly affect the grinding efficiency of the sand mill. 1. Relative density Relative density should be expressed in term

Alumina ceramic balls will be used by more and more ceramic manufacturers. According to different alumina content, they can be divided into medium aluminum balls, medium and high alumina balls and high alumina balls. Generally, we classify 60%-65% alumina content as Medium aluminum balls, those with 75%-80% alumina content are called medium and high aluminum balls, and those with more than 90% alumina content are high aluminum balls.

*文章标题 *文章简介 How to improve the grinding efficiency of ceramic balls. "The sand mill converts chemical energy into crushing energy for raw materials through grinding. Its basic principle is to disperse and pulverize raw material particles by friction, cutting and impact in the middle of grinding. The relative density, strength, particle size and filling rate of the grinding directly affect the grinding efficiency of the sand mill. 1. Relative density Relative density should be expressed in term

It is best to use ceramic lining bricks for the inner lining of the ball mill. The appearance of the ceramic lining bricks of the ball mill is fine and white, and the two lining bricks are connected by snap buttons to ensure the connection strength. Its main component is high-quality alumina, which has high whiteness and has no adverse effect on the quality of the ground material. There are five types of ceramic lining bricks for ball mills, namely straight bricks, inclined bricks, straight half

English

English