Our business covers the areas of producing, purchasing, owning, and operating hydroelectric projects, wind farms, solar energy plants, and energy storage centers. aluminium grinding balls,

75% alumina ball, silex bricks, mining grinding, Our competent, responsible and well-trained team is prepared to construct prosperous, mutually advantageous business ties with you soon. Do not hesitate to contact us if you need more info., Ireland, Turin, Brisbane, Due to our regular attempt for satisfactory and after-sales service, our product is becoming an increasing number of popular all over the world, with severa consumers coming to go to our manufacturing unit and make orders. Our merchandise are designed to swimsuit your desires and we warranty pleasure with each purchase. Wear-resistant alumina ceramic lining is a special type of ceramic with a relatively dense structure and special propert

1. Power saving: reduce the loading capacity of the grinding body of the mill by 20%, reduce the current of the main mac

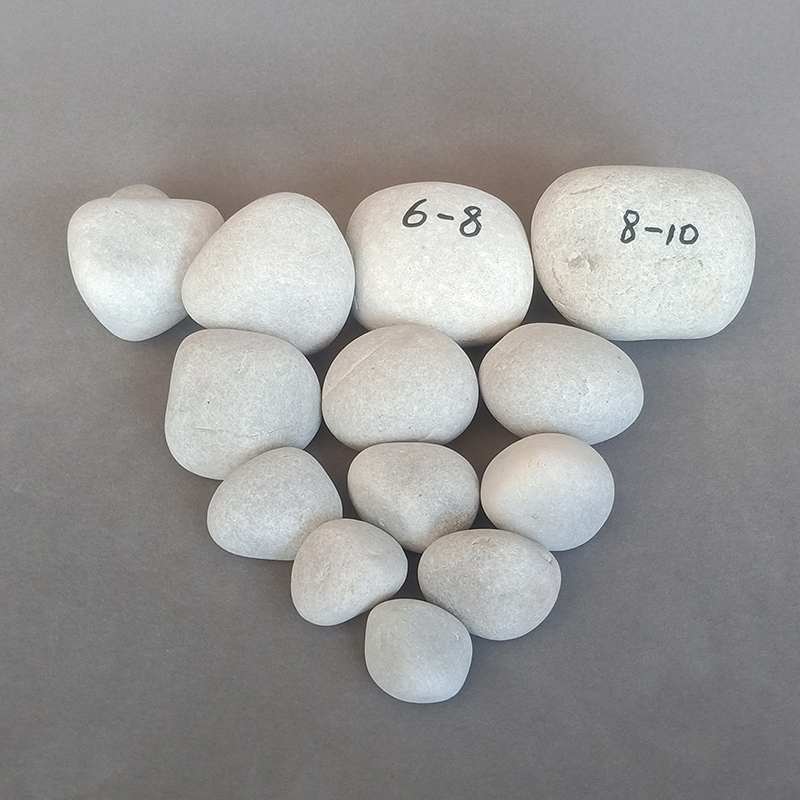

Both steel grinding balls and alumina ceramic grinding balls are widely used as grinding media for kinds industries.Here

Ball mills are a type of grinding equipment widely used in industries such as abrasives, chemicals, and building materia

Wear-resistant ceramic lining is a material mainly made of alumina (AL2O3), supplemented with other ingredients, and sintered at a high temperature of 1700°C. It is widely used in thermal power, steel, smelting, machinery, coal, mining, chemical industry, Different types of products can be selected according to different needs for coal conveying, material conveying systems, pulverizing systems, ash discharge, dust removal systems and other mechanical equipment with heavy wear in cement, port and

*文章标题 *文章简介 How to improve the grinding efficiency of ceramic balls. "The sand mill converts chemical energy into crushing energy for raw materials through grinding. Its basic principle is to disperse and pulverize raw material particles by friction, cutting and impact in the middle of grinding. The relative density, strength, particle size and filling rate of the grinding directly affect the grinding efficiency of the sand mill. 1. Relative density Relative density should be expressed in term

*文章标题 *文章简介 How to improve the grinding efficiency of ceramic balls. "The sand mill converts chemical energy into crushing energy for raw materials through grinding. Its basic principle is to disperse and pulverize raw material particles by friction, cutting and impact in the middle of grinding. The relative density, strength, particle size and filling rate of the grinding directly affect the grinding efficiency of the sand mill. 1. Relative density Relative density should be expressed in term

It is best to use ceramic lining bricks for the inner lining of the ball mill. The appearance of the ceramic lining bricks of the ball mill is fine and white, and the two lining bricks are connected by snap buttons to ensure the connection strength. Its main component is high-quality alumina, which has high whiteness and has no adverse effect on the quality of the ground material. There are five types of ceramic lining bricks for ball mills, namely straight bricks, inclined bricks, straight half

English

English