We create, buy, possess, and function hydroelectric plants, wind generators, solar farms, and energy reservoirs at a corporate level. Zirconium aluminum ceramic balls,

ceramic alumina ball, Ready to press powder, alumina grinding balls, We can help you establish your business, even if you're overseas., El Salvador, Berlin, Afghanistan, We are pledged to environmental permanence and judicious fabrication procedures, allowing us to fabricate energy of outstanding excellence while cutting our ecological outcome. Dalian Gaoteng not only provide alumina grinding balls and flint pebbles ,we also supply zirconium-aluminum composite ba

Optical glassCordierite has good optical properties, including high transparency, low scattering, and excellent refract

Choosing high-quality high-alumina grinding balls is crucial for efficient and effective grinding processes. Here are so

On this Mid-Autumn Festival, with a grateful heart, we appreciate your continued trust and support for Dalian Gaoteng.In

A1. Principle of the methodThis method is based on placing alumina ball within the polyurethane jar and test for grindin

Wear-resistant ceramic lining is a material mainly made of alumina (AL2O3), supplemented with other ingredients, and sintered at a high temperature of 1700°C. It is widely used in thermal power, steel, smelting, machinery, coal, mining, chemical industry, Different types of products can be selected according to different needs for coal conveying, material conveying systems, pulverizing systems, ash discharge, dust removal systems and other mechanical equipment with heavy wear in cement, port and

*文章标题 *文章简介 How to improve the grinding efficiency of ceramic balls. "The sand mill converts chemical energy into crushing energy for raw materials through grinding. Its basic principle is to disperse and pulverize raw material particles by friction, cutting and impact in the middle of grinding. The relative density, strength, particle size and filling rate of the grinding directly affect the grinding efficiency of the sand mill. 1. Relative density Relative density should be expressed in term

It is best to use ceramic lining bricks for the inner lining of the ball mill. The appearance of the ceramic lining bricks of the ball mill is fine and white, and the two lining bricks are connected by snap buttons to ensure the connection strength. Its main component is high-quality alumina, which has high whiteness and has no adverse effect on the quality of the ground material. There are five types of ceramic lining bricks for ball mills, namely straight bricks, inclined bricks, straight half

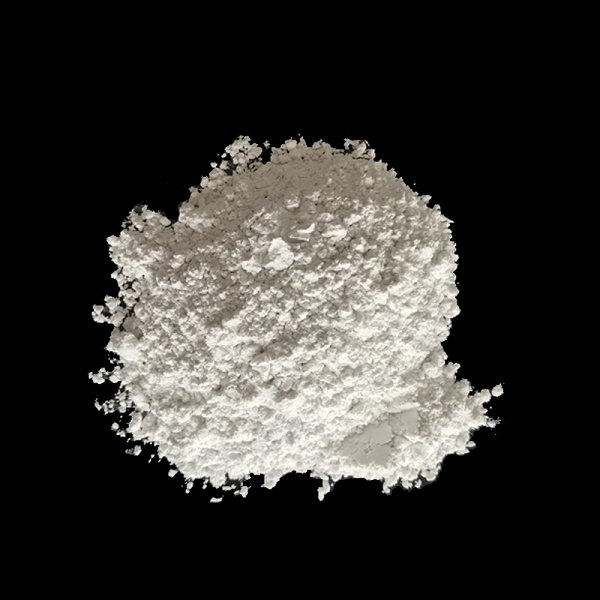

Alumina ceramic balls will be used by more and more ceramic manufacturers. According to different alumina content, they can be divided into medium aluminum balls, medium and high alumina balls and high alumina balls. Generally, we classify 60%-65% alumina content as Medium aluminum balls, those with 75%-80% alumina content are called medium and high aluminum balls, and those with more than 90% alumina content are high aluminum balls.

English

English