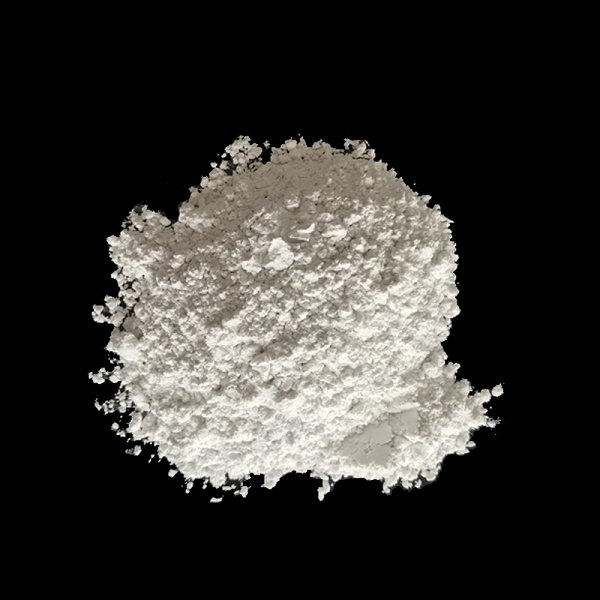

We can now supply industrial equipment and components companies with our own production and service organization and we are able to offer every kind of product associated with our solutions selection, such as... Alumina Ceramic Grinding,

alumina oxide lining, silica pebbles for grinding, alumina granulating powder, We are positive that our dependable, expert and skilled group can set up profitable, at the same time really useful commercial enterprise connections with you shortly. Feel free to contact us if extra statistics is needed., Birmingham, Senegal, Haiti, We have long experience in the art of ironwork, ore, and energy and have secured successful outcomes both at home and abroad. Silica quartz sand can be a beneficial amendment for afforestation (planting trees in areas that have historically lacke

Dalian Gaoteng International Logistics Company already has 25 years of history. We can support One-stop container import

Silica sand is a material with very good chemical stability. It can exist stably for a long time at high temperature wit

Fumitec corporation is supplier of High Purity Quartz Powder covering the Semiconductor needs of Japan, Korea, Thailand,

*文章标题 *文章简介 How to improve the grinding efficiency of ceramic balls. "The sand mill converts chemical energy into crushing energy for raw materials through grinding. Its basic principle is to disperse and pulverize raw material particles by friction, cutting and impact in the middle of grinding. The relative density, strength, particle size and filling rate of the grinding directly affect the grinding efficiency of the sand mill. 1. Relative density Relative density should be expressed in term

It is best to use ceramic lining bricks for the inner lining of the ball mill. The appearance of the ceramic lining bricks of the ball mill is fine and white, and the two lining bricks are connected by snap buttons to ensure the connection strength. Its main component is high-quality alumina, which has high whiteness and has no adverse effect on the quality of the ground material. There are five types of ceramic lining bricks for ball mills, namely straight bricks, inclined bricks, straight half

*文章标题 *文章简介 How to improve the grinding efficiency of ceramic balls. "The sand mill converts chemical energy into crushing energy for raw materials through grinding. Its basic principle is to disperse and pulverize raw material particles by friction, cutting and impact in the middle of grinding. The relative density, strength, particle size and filling rate of the grinding directly affect the grinding efficiency of the sand mill. 1. Relative density Relative density should be expressed in term

Wear-resistant ceramic lining is a material mainly made of alumina (AL2O3), supplemented with other ingredients, and sintered at a high temperature of 1700°C. It is widely used in thermal power, steel, smelting, machinery, coal, mining, chemical industry, Different types of products can be selected according to different needs for coal conveying, material conveying systems, pulverizing systems, ash discharge, dust removal systems and other mechanical equipment with heavy wear in cement, port and

English

English