We are a high-tech organization dedicated to technological know-how innovation, product innovation and administration innovation in classification of grinding balls,

flint pebbles for grinding tripoli, silex liner, silica quartz sand, Furthermore, extra after-sales service is available such as lifetime maintenance at a reasonable cost and spare parts supply., Cannes, Johannesburg, Manchester, Due to our constant strive for quality and after-sales service, our product is becoming increasingly popular all over the world, with numerous clients coming to visit our factory and make orders. Our products are designed to suit your needs and we guarantee satisfaction with every purchase. Grinding is the fundamental process of powder deep processing, which is not only a refining process, but also a mixing a

Dalian Gaoteng International Logistics Company already has 25 years of history. We can support One-stop container import

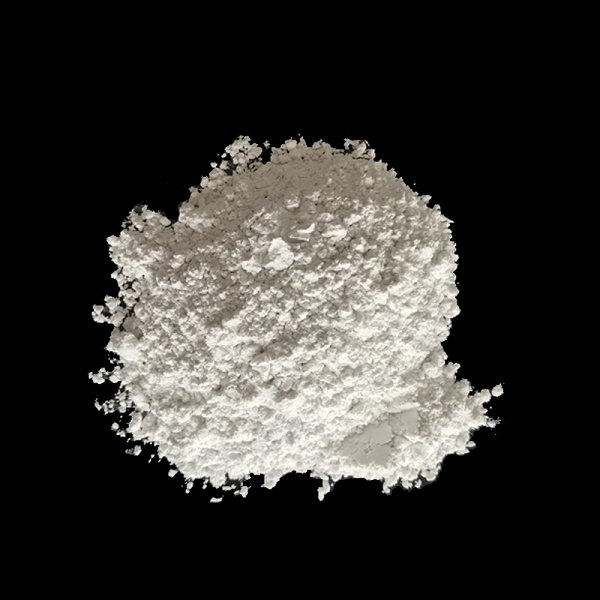

Fumitec corporation is supplier of High Purity Quartz Powder covering the Semiconductor needs of Japan, Korea, Thailand,

Widely usage of alumina grinding balls for the following fields:1. Ceramic industry: Alumina grinding balls are used as

Silica quartz sand can be a beneficial amendment for afforestation (planting trees in areas that have historically lacke

Alumina ceramic balls will be used by more and more ceramic manufacturers. According to different alumina content, they can be divided into medium aluminum balls, medium and high alumina balls and high alumina balls. Generally, we classify 60%-65% alumina content as Medium aluminum balls, those with 75%-80% alumina content are called medium and high aluminum balls, and those with more than 90% alumina content are high aluminum balls.

It is best to use ceramic lining bricks for the inner lining of the ball mill. The appearance of the ceramic lining bricks of the ball mill is fine and white, and the two lining bricks are connected by snap buttons to ensure the connection strength. Its main component is high-quality alumina, which has high whiteness and has no adverse effect on the quality of the ground material. There are five types of ceramic lining bricks for ball mills, namely straight bricks, inclined bricks, straight half

Wear-resistant ceramic lining is a material mainly made of alumina (AL2O3), supplemented with other ingredients, and sintered at a high temperature of 1700°C. It is widely used in thermal power, steel, smelting, machinery, coal, mining, chemical industry, Different types of products can be selected according to different needs for coal conveying, material conveying systems, pulverizing systems, ash discharge, dust removal systems and other mechanical equipment with heavy wear in cement, port and

Wear-resistant ceramic lining is a material mainly made of alumina (AL2O3), supplemented with other ingredients, and sintered at a high temperature of 1700°C. It is widely used in thermal power, steel, smelting, machinery, coal, mining, chemical industry, Different types of products can be selected according to different needs for coal conveying, material conveying systems, pulverizing systems, ash discharge, dust removal systems and other mechanical equipment with heavy wear in cement, port and

English

English