Our company is responsible for creating and managing hydroelectricity, wind turbines, solar energy, and storage operations. 80% Alumina Balls, silica pebbles for grinding, silex blocks, silex liner, We dispense a project turnkey solution which involves online technical support, professional drawing designs, efficient production arrangement, field installation, and operator training and many more.

Product introduction:

Silica pebbles is mined in mines. It has the characteristics of high silicon, low iron, high density and wear resistance, smooth surface. And is a high-quality grinding medium. Silica pebbles have three different grades: Grade A, Grade B, Grade C, respectively.

SiO2 as the main content of silica pebbles, is the indispensable raw materials in ceramic production. Which has an important impact on the properties and quality of ceramics.

First, the silica content determines the hardness and compressive strength of the ceramic. When making ceramics, the appropriate addition of silicon can increase the harness and stablility of the ceramic body, so that the ceramic has better wear resistance and durability.

Secondly, the content of silica will also affect the fine degree and texture of the ceramic. Higher content of silica can improve the sintering temperature and sintering density of ceramics, making the porcelain body more dense and uniform, thus showing a more delicate texture and surface quality.

In addition, the silica content will directly affect the whiteness and light transmittance of ceramics. For the production of white porcelain and transparent porcelain, it is necessary to use a high content of silica to make the porcelain body appear white and bright and good light transmission.

Technical specification:

Product features:

High SiO2 with low Fe2O3 contents

High density and hardness and low abrasion

Good roundness

Consistent specification

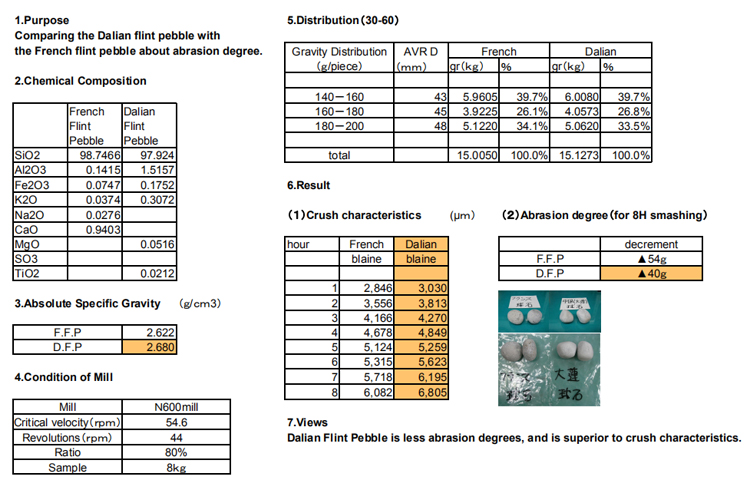

Comparison report:

Under the same test condition, test report from our Japanese customer show the difference from our Dalian pebbles & French pebbles:

Density: 2.68g/cm3 of Dalian pebbles higher than 2.62g/cm3 of french pebbles.

Wear loss: wear loss of Dalian pebbles is 40g, less than 50g of french pebbles.

Our advantages and services:

Dalian Gaoteng was established in 2000, has rich export experience, cooperate with over 200 customers, often export to Japan, Southeast Asia, Europe, the middle east…

Due to customers from different industries could have different requirement, we can help you to choose suitable product.

Besides, we have own logistics company, can offer the best service and favorable price to you.

Application field:

Due to Gaoteng silica pebbles with high silicon content, low wear loss, high density, are widely used in sanitary ware industry, table ware industry, tiles industry, white cement industry, glass industry, etc.

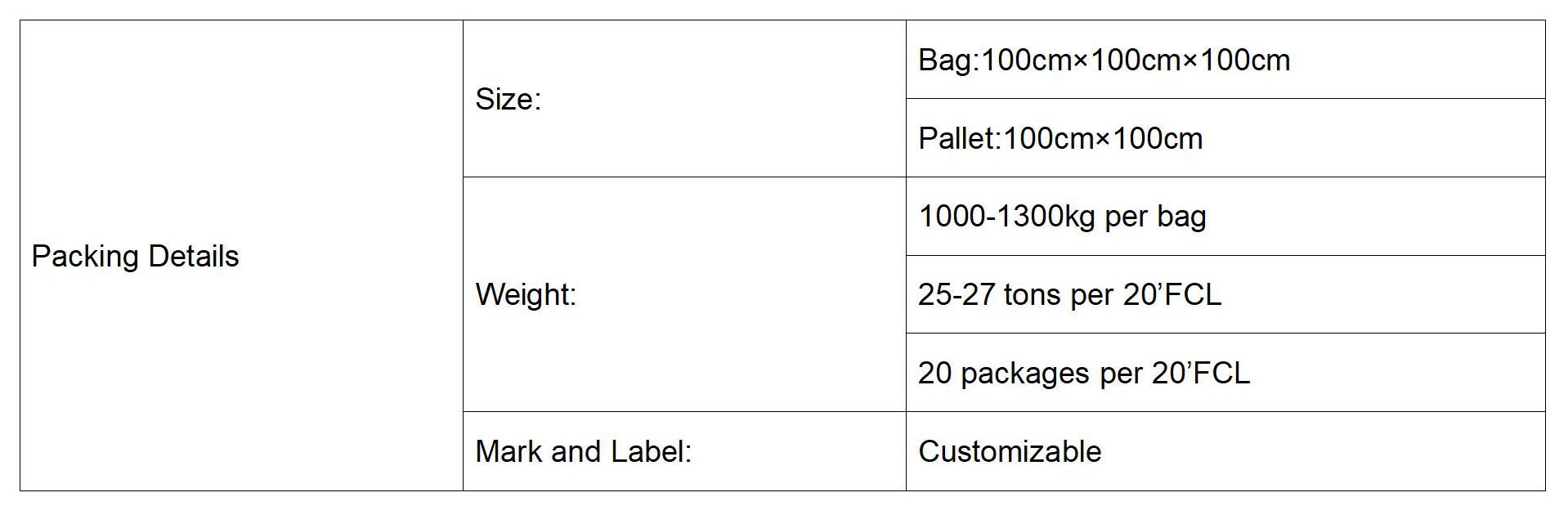

Packing details:

Jumbo Bags

One Bag With One Pallet

Two Bags With Pallet

In Bulk

Production process:

We trust in a top-quality sphere the place bounteous renewable power will increase healthful communes and forges shared opulence. high quality Silica Pebbles manufacturer, The product will supply to all over the world, such as: Uzbekistan, Manchester, Nicaragua, Lebanon, We are devoted to ecological sustainability and conscientious fabrication tactics, permitting us to create energy of high-grade quality while minimizing our environmental impact.