As a knowledge-intensive high-tech enterprise with great potential, the company has sustained and stable development for Zirconia beads, silica stone, ball mill lining, Alumina balls, Our assortment of components caters to great industry interests. As a professional manufacturer of metallurgy, mineral & energy, our products are suitable for many kinds of solutions.

Product breif introduction & Application:

Flint pebbles are commonly used in the ceramic industry for various applications such as grinding clay, feldspar, and quartz. These pebbles are characterized by their hardness, resistance to abrasion, and durability, which means that they can be used for extended periods of time without needing to be replaced. Additionally, flint pebbles do not contain any impurities that could affect the quality of the finished product.

Overall, flint pebbles are an essential component of the ceramic industry (Sanitary ware, Table ware, Tiles, etc.), providing a durable and effective grinding medium that helps to produce high-quality ceramics.

The focus of different ceramic industries is different:

Tableware/Decorative ceramics: Focus on whiteness and purity (higher SiO₂ grades).

Building ceramics (tiles): Emphasize sintering activity and thermal stability for fast firing.

Technical ceramics (e.g., refractories): Require high refractoriness and thermal shock resistance, with slightly higher impurity tolerance.

Meanwhile, flint pebbles can be used in white cement industry, fiberglass industry, etc.

Technical data:

Product features:

Flint pebbles for ceramic industry with high purity: Over 99% SiO2 with low Fe2O3 contents

High density, superior hardness and low abrasion

Good roundness: Improve grinding efficiency

Consistent specification: Strict quality testing

The recommended sizes for flint pebbles to be used as Grinding media

Size | Little Size | Medium Size | Large Size |

Product Photo |

|

|

|

Size Range | 2-4cm | 5-7cm | 10-12cm |

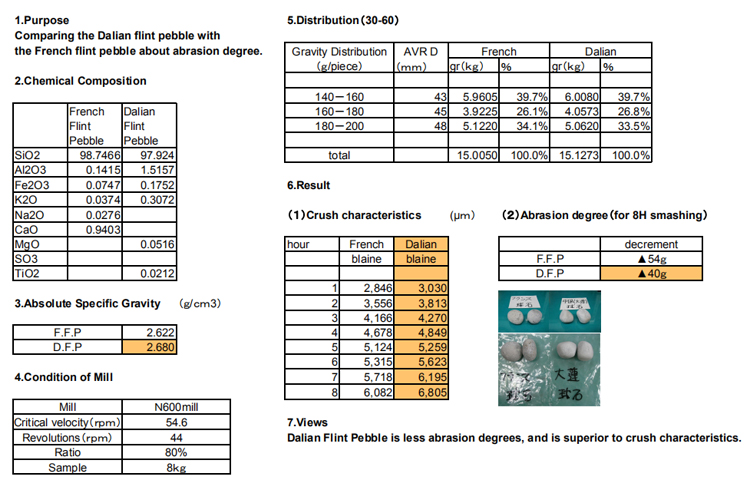

Comparison report:

Under the same test condition, test report from our Japanese customer show the difference from our Dalian pebbles & French pebbles:

Density: 2.68g/cm3 of Dalian pebbles higher than 2.62g/cm3 of french pebbles.

Wear loss: wear loss of Dalian pebbles is 40g, less than 50g of french pebbles.

Our advantages and services:

Founded in 2000, Dalian Gaoteng has extensive export experience, working with more than 200 customers and exporting frequently to Japan, Southeast Asia, Europe and the Middle East .

Since customers from different industries have different requirements, we can help you choose a suitable product.

In addition, we have our own logistics company. We can offer you the best service and a favorable price.

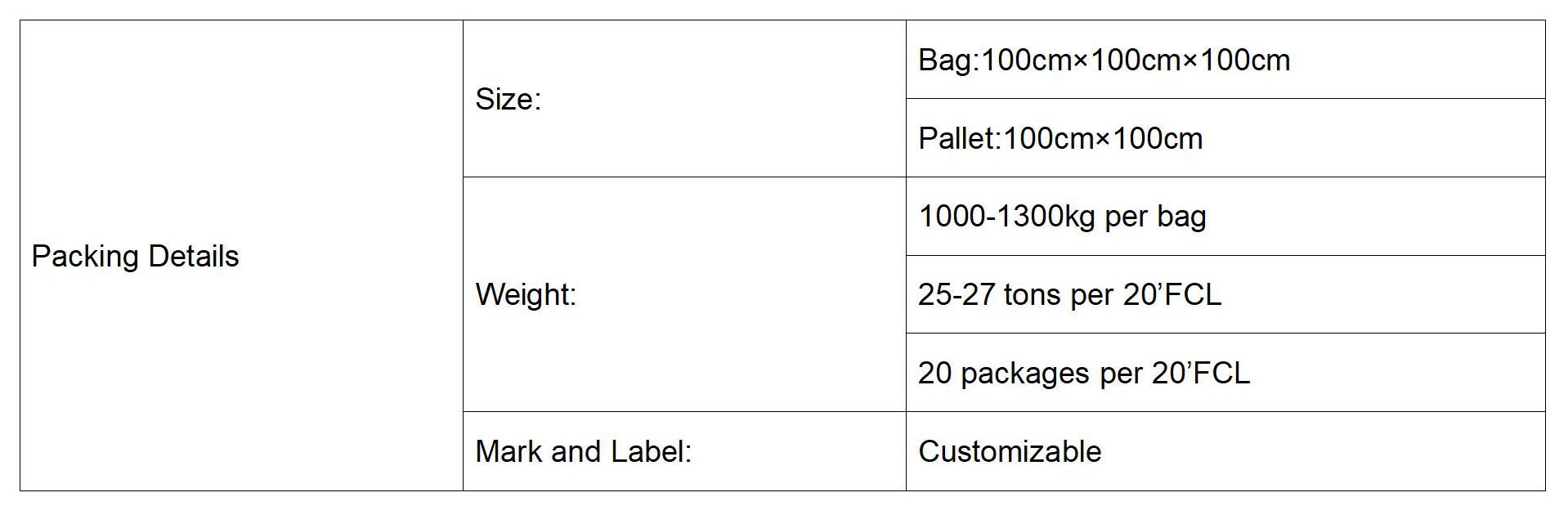

Packing details:

Jumbo Bags

One Bag With One Pallet

Two Bags With Pallet

In Bulk

Production process:

We think about a best area the place sufficient renewable may aids nourishing societies and generates frequent opulence. high hardness Flint Pebbles for Ceramic Industry china, The product will supply to all over the world, such as: United Kingdom, British, Cannes, San Diego, We are pledged to environmental durability and mindful fabrication operations, providing us to make energy of perfect grade while encumbering our environmental effect.