As a knowledge-intensive high-tech organisation with terrific potential, the agency has sustained and steady improvement for Silica lining bricks, 68% Alumina Balls, silica pebbles for Catalyst pad, alumina bricks, Our project turnkey solution gives you access to online technical support, professional drawing designs, effective production arrangement, field installation and operator training, among other things.

Product introduction & Application:

Silica pebbles play a pivotal role as the grinding media in the white cement industry. Considering the consumption and cost aspects, grade C pebbles are typically the preferred choice for this sector.

During the production of white cement, use silica pebbles to grind clinker within ball mills. Being an essential grinding medium, these pebbles serve to reduce the particle size of the clinker. In comparison to other grinding media (steel balls), silica pebbles have a distinct advantage in terms of their reduced abrasiveness. And can decrease iron contamination in the white cement, thereby minimizing the possible discoloration that may occur.

And we have cooperated with white cement plants in Malaysia since 2014. Their annual consumption can be over 4000 tons.

Apart from their use in the white cement industry, silica pebbles find applications in other sectors as well, such as in the sanitary ware, tableware, tiles, glass, and zirconium silicate industries.

Technical data:

Product features:

Silica pebbles for white cement industry are high SiO2 with low Fe2O3 contents

High density and hardness and low abrasion

High efficiency and low costs

Consistent specification

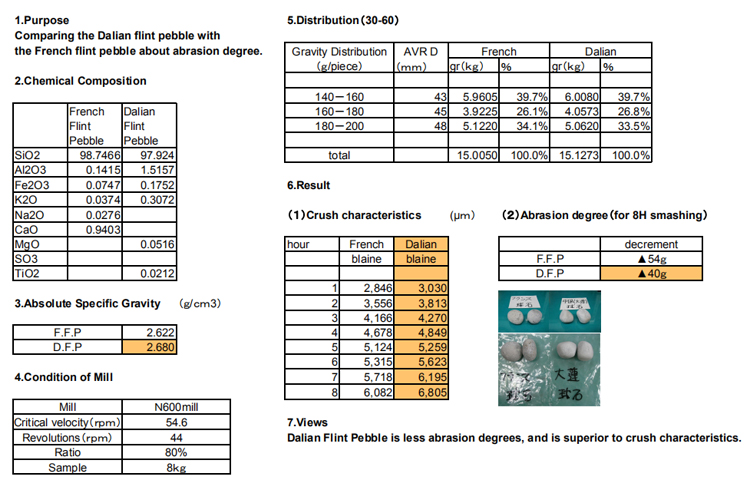

Comparison report:

Under the same test condition, test report from our Japanese customer. Which shows the difference from our Dalian pebbles & French pebbles:

Density: 2.68g/cm3 of Dalian pebbles higher than 2.62g/cm3 of french pebbles.

Wear loss: wear loss of Dalian pebbles is 40g, less than 50g of french pebbles.

Our advantages and services:

Dalian Gaoteng, established in 2000, is well-versed in exporting with over 200 clients. Our frequent exports to regions including Japan, Southeast Asia, Europe, and the Middle East.

In order to cater to the diverse needs of our clients from various industries, we offer advisory services to ensure the selection of suitable products.

Moreover, our logistics company offers optimal logistic solutions at competitive rates, which guarantees the highest level of service to our valued clients.

Tips:

As the white cement grinding media, if the silica pebbles contain the excessive following substances, may cause harm to the white cement industry:

Fe2O3 content: The higher the Fe2O3 content in silica pebbles, the greater the grinding effect of white cement, but the content needed within the standard, if exceeded, will affect the color and quality of white cement, causing adverse effects, even unable to meet the specified standards.

Cr, Ni, Cu, and other toxic metals content & radioactive element content: If there is too much harmful content, it may cause pollution of white cement products, affecting product quality, employee health, and the environment.

Unconsumed fuel residue: If the silica pebbles can't burned or crushed completely in the production process, will contain unconsumed fuel residue, which will cause problems such as black spots and black slag of the final product.

Therefore, the factories need to select superior silica pebbles as grinding media, to ensure product quality, employee health, and environment safety.

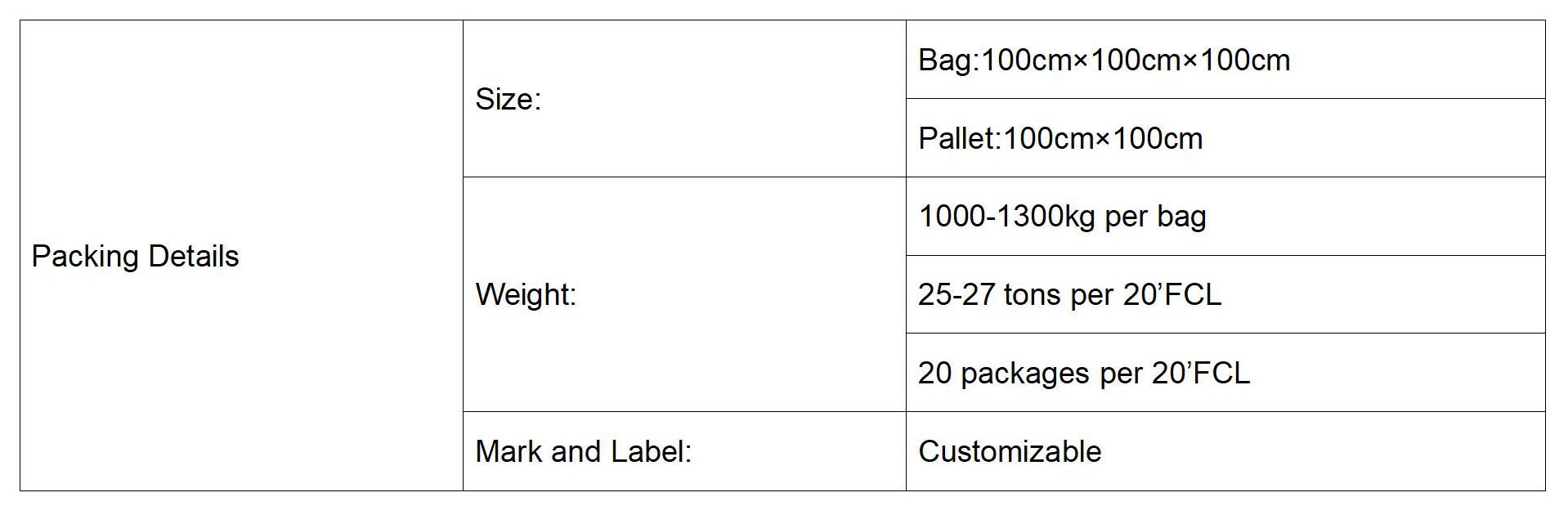

Packing details:

Jumbo Bags

One Bag With One Pallet

Two Bags With Pallet

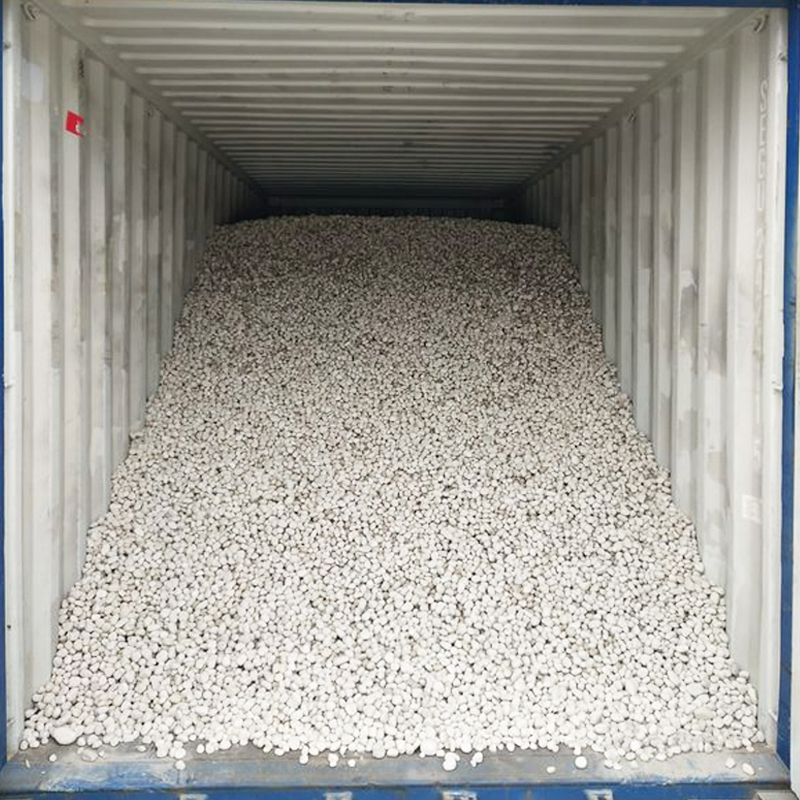

In Bulk

Production process:

Our challenge is devoted to gaining, holding, assembling, and running hydroelectric complexes, wind fields, photo voltaic electricity units, and electricity deposits. good quality Silica Pebbles for White Cement Industry manufacturer, The product will supply to all over the world, such as: Hyderabad, Oslo, European, Rio de Janeiro, Our plentiful knowledge in metalworking, ore, and energy has reaped victories both locally and overseas.