Our establishment is tasked with gaining, buying, owning, and administering hydroelectric complexes, wind turbines, solar power plants, and energy storage tanks. grinidng media, cordierite, milling stone, Silica lining bricks, Furthermore, extra after-sales service is available such as lifetime maintenance at a reasonable cost and spare parts supply.

Brief introduction & Application:

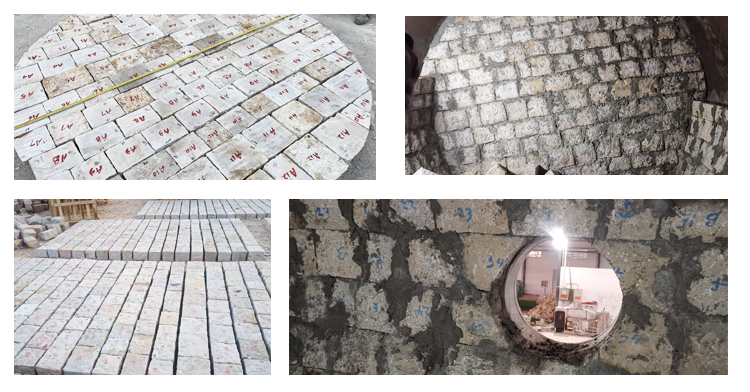

The hand-made silex lining bricks can be customized according to the size of the customer's ball mill. Our workers have more than 30 years' processing experience. The hand-made silex lining bricks have high flatness, can install easier and serve for long time.

Silex lining bricks have the high-quality characteristics of high SiO2, low Fe2O3 content, high hardness, and low wear. They are suitable for grinding various raw materials, widely used in the ceramic industry, such as ceramic tiles, tableware, sanitary ware, and ceramic handicrafts; Suitable for white cement, zirconium silicate, quartz, glass, and other chemical industries.

Size:

Body (Cylinder) / Sidewall(End surface) | |

Length | 200-350mm |

Width | 150-220mm |

Thickness | 110-200mm |

Can be customized according to ball mill size. | |

Technical data:

SiO2 | ≥99.31% | Volume density | ≥2.66g/cm3 |

Al2O3 | ≤0.36% | Using life | over 3 years (refer to the raw materials) |

Fe2O3 | ≤0.018% | Porosity | ≤0.38% |

CaO | 0.09% | Hardness | Around 8 |

MgO | 0.04% | Color of product after burning | White |

Why choose us?

Feature:

* The stone is fine with high density,improve grinding efficiency.

* Mohs hardness 7-8, has good wear resistance.

* High SiO2 and low Fe2O3 content: the stone has high purity, avoiding impurities and pollution during the grinding process, ensuring stable quality of end products.

* Wide range of application: SiO2 is the main component of silex lining stone, and the product can be applied to the grinding of various chemical raw materials without affecting the chemical composition.

Service:

*Professional artisans: Our artisans have over 30 years experience of processing silex blocks.

*Installation: We will draw diagram according to customer's ball mill size, marked number on the bricks, so that customers can install without processing again.

*Exportation experience: Almost 99% products exported to more than 40 countries and regions all over the world, we mainly serve to Japan, Bangladesh, India and South East Aisa, etc.

*Logistics: Our own Dalian Gaoteng International logistics company founded in 2000, would provide timely and efficient logistics services for all customers.

Packing details:

Type | Bag |

Size | Bag:100cm x 100cm x 100cm Wooden cases |

Weight: | 1000-1300kg per bag |

Mark and Label: | Customizable |

Processing:

Firstly, workers utilize air compressors to power pneumatic picks, drilling holes into large stones.

Subsequently, wedges are hammered into these holes to split the stones apart.

Afterward, based on the required thickness, the stones are processed into standardized sizes.

Furthermore, we can also provide finished silex lining bricks according to the specifications of customers' ball mills.

In this process, workers conduct secondary fine processing to ensure a smoother stone surface and minimize gaps during fitting.

The grinding head and body are processed separately, and each stone is numbered for easy installation by customers.

Additionally, we offer free processing of feed and discharge holes for our clients.

We strive for excellence in every detail and maintain strict quality control.

We are a high-tech corporation dedicated to technological know-how innovation, product innovation and administration innovation in customized Silex Lining Bricks supplier, The product will supply to all over the world, such as: Sudan, Canberra, Southampton, Greenland, Our items amassed a renowned repute due to their robust performance, equitable fee, and superior after-sale aid.