We envision a remarkable universal where abundant sustainable strength bolsters healthy fellowships and produces mutual prosperity. 92% Alumina lining, flint pebbles, silex blocks, Manual silex lining, As a result of the technical and operational excellence of our personnel worldwide, we are able to look forward to the future with optimism.

Product introduction:

Flint pebble is a high quality ceramic grinding media for ball mill, can grind ceramic raw materials(feldspar, quartz, Kaolin), cement and glass raw materials. Flint pebbles(silica pebbles) have three different grades divided by roundness: Grade A, Grade B and Grade C.

Technical indicator:

SiO2 | ≥99.31% | Volume density | ≥2.66~2.68g/cm3 |

Al2O3 | ≤0.36% | Hardness | Around 8 mohs |

Fe2O3 | ≤0.018% | Porosity | ≤0.38% |

CaO | 0.09% | Actual abrasion rate | ≤1.35 |

MgO | 0.04% | Color | Grey and White |

Product features:

High SiO2 with low Fe2O3 contents

High density and hardness and low abrasion

Good roundness

Consistent specification

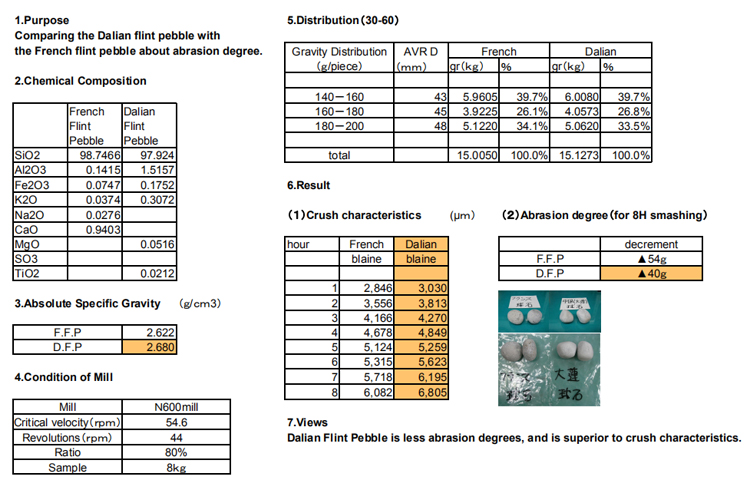

Comparison report:

Under the same test condition, test report from our Japanese customer show the difference from our Dalian pebbles & French pebbles:

Density: 2.68g/cm3 of Dalian pebbles higher than 2.62g/cm3 of french pebbles.

Wear loss: wear loss of Dalian pebbles is 40g, less than 50g of french pebbles.

Our advantages and services:

Dalian Gaoteng was established in 2000, has rich export experience, cooperate with over 200 customers, often export to Japan, Southeast Asia, Europe, the middle east…

Due to customers from different industries could have different requirement, we can help you to choose suitable product.

Besides, we have own logistics company, can offer the best service and favorable price to you.

Application field:

*Flint Pebbles are widely used as grinding media or filling material to grind a variety of raw materials in a ball mill.

*They are widely used for different industries, such as the ceramic industry, glass industry, white cement, zirconium silicate industry, as well as insulated electric porcelain, etc.

*For the ceramic industry, flint pebbles can be used for ceramic tiles, sanitary ware, tableware… grind kaolin, feldspar, glaze material, etc.

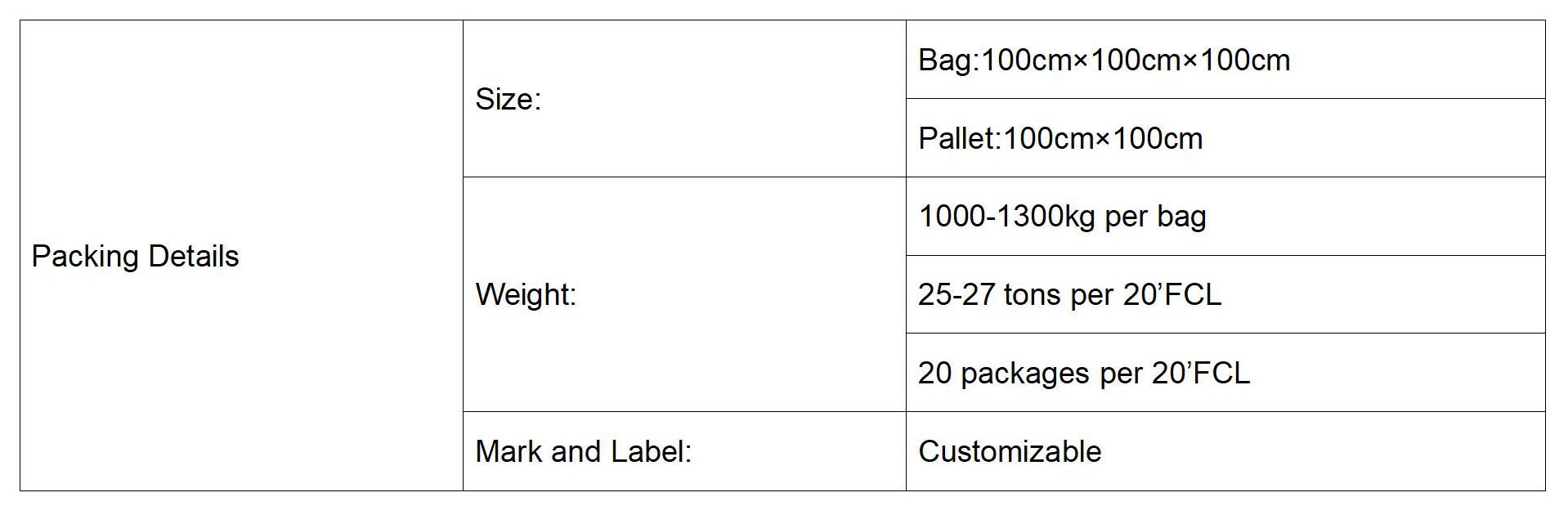

Packing details:

Production process:

Tips--How to choose the excellent flint pebbles?

Choosing the suitable flint pebbles is nacessary for ceramic industry. When select it, need to pay attention on following tips:

Hardness of flint pebbles: The higher the flint pebbles, the longer the service life, won't easily wear in the production process. Meanwhile, the higher the hardness, the grinding out the more delicate the material, and the better the quality.

The sizes of flint pebbles: In general, the smaller the size of flint pebbles, the more delicate the material grinding out. However, the size of the stone should also be flexibly determined according to the specific situation, and can not be generalized.

The purity of flint pebbles: High purity silica can ensure the quality of the material grinding out, but also ensure the service life and stability of silica pebbles.

The wear-resistance of flint pebbles: The wear-resistant silica pellet will not break or break after a long time of use, and can maintain a good grinding effect for a long time.

Our venture is involved with acquiring, having, forming, and functioning hydroelectric facilities, wind turbines, solar power stations, and energy storages. customized Flint Pebbles supplier, The product will supply to all over the world, such as: Greek, Costa Rica, Bahamas, Congo, Our items earned a distinguished recognition thanks to their dependable operation, sensible fee, and superior after-sale aid.