We are an independent renewable power producer which develops, acquires, owns and operates hydroelectric facilities, wind farms, solar farms and energy storage facilities. ceramic pebbles, grinding pebbles, silex blocks, Manual silex lining, We provide a project turnkey solution that contains online technical support, professional drawing designs, efficient production arrangement, field installation and operator training, and various other services.

Product introduction & Application:

Silica stones are widely used as grinding media in the glass industry. Silica stones are chosen for their high purity (over 99% silicon content), hardness, low wear rate, and resistance. Ensuring that the raw material is not affected during grinding.

Silica stones mainly contain SiO2, Al2O3, Fe2O3, CaO, MgO, and other components, and they have different effects on the manufacture and performance of glass.

First, SiO2 in silica stones is one of the main contents of the glass, which gives the glass excellent high-temperature resistance, chemical stability, and transparency. Therefore, the SiO2 content in silica stones directly affects the quality of glass products. In general, the glass industry used silica stone should contain more than 98% SiO2, so as to ensure the quality and stability of the glass.

Secondly, the composition of Fe2O3, Cao, and MgO in the silica stone also has a certain impact on the quality of the glass. Among them, the lower the content of Fe2O3, the more transparent the color of the glass produced, the better quality. CaO and MgO can improve the thermal conductivity and solubility of the glass, making the product's durability more excellent.

Finally, the Al2O3 content in the silica stone is also an important factor affecting the glass industry. Generally, a high Al2O3 content of silica stones will reduce the softening point of the glass, thereby reducing the strength and stability of the glass. Therefore, the silica stones used in the glass industry require the Al2O3 content to be less than 1%.

We stably supplied silica stones to Taiwan Glass, which is TOP 500, since 2017.

Moreover, silica stones are also used in the ceramic industry, white cement industry, zirconium silicate industry, etc.

Technical indicator:

Product features:

High hardness: Ensure the glass materials can be effectively ground, the hardness is 7~8mohs.

Favorable wear-resistance: Can maintain the good particle shape and size after a long grinding process, which will help to provide a stable grinding effect.

Stable chemical property: The chemical of silica stones is stable, not easily react with other substances. Can avoid contamination or impact on the glass materials.

Uniform sizes: The size of the silica stones are relatively uniform, to ensure a consistent grinding effect during the grinding process.

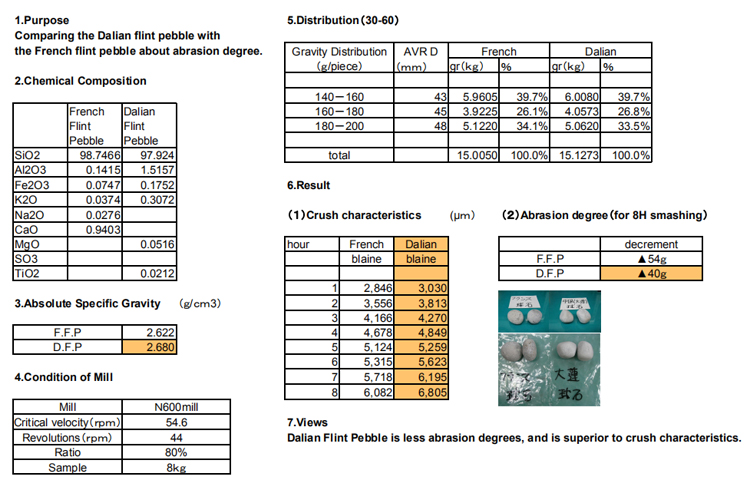

Comparison report:

Under the same test conditions, a test report from our Japanese customer shows the difference between our Dalian pebbles & French pebbles:

Density: 2.68g/cm3 of Dalian pebbles is higher than 2.62g/cm3 of French pebbles.

Wear and tear: Dalian pebbles have 40g of wear and tear, less than 50g of French pebbles.

Our advantages and services:

Founded in 2000, Dalian Gaoteng has extensive export experience, working with more than 200 customers and regularly exporting to Japan, Southeast Asia, Europe and the Middle East .

Customers from different industries may have different requirements, so we can help you choose the right product.

In addition, we have our own logistics company that can provide you with the best service and favorable prices.

Packing details:

Jumbo Bags

One Bag With One Pallet

Two Bags With Pallet

In Bulk

Production process:

Our company is responsible for creating and managing hydroelectricity, wind turbines, solar energy, and storage operations. chinese Silica Stone for Glass Industry supplier, The product will supply to all over the world, such as: Afghanistan, Irish, Bangkok, Southampton, Using advanced energy production equipment and high quality materials, we ensure our energy products are high quality, reliable, and perform well.