We envision a superior world where plentiful green energy fortifies more robust people and fabricates mutual success. Alumina lining bricks, Silica lining bricks, alumina grinding balls, flint stone, Further after-sales service is obtainable in the form of lifetime maintenance for a pocket-friendly rate, coupled with spare parts supply.

Brief introduction & Application:

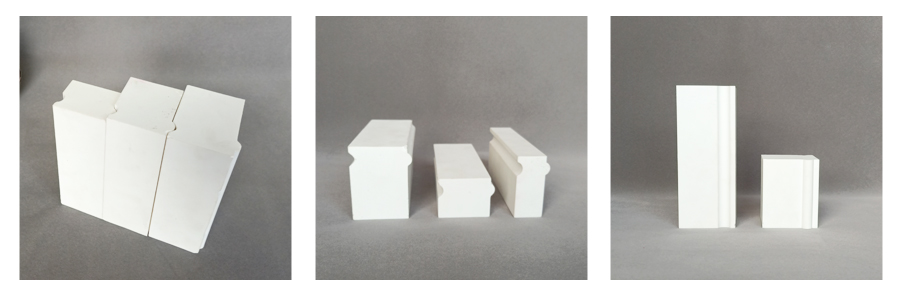

92% Alumina bricks as one of the most common ball mill liner, has good hardness, low wear loss, can improve grinding efficiency effectively, reduce production costs and pollution, widely applicate in many industries.

Such as:

Ceramics, mines and other grinding equipment lining

Material transfer equipment,

Inside and outside surface of powder separating equipment on iron and steel works

Thermal and power plants

Coals and cements industries,etc.

Technical data:

Item | Result |

Al2O3 | 92 % |

Hardness | 9 Mohs |

Density | 3.60 g/cm3 |

Sizes:

Brick Type | Length(mm) | Width1(mm) | Width2(mm) | Height(mm) |

Rectangle Brick | 150 | 50 | 50 | 40,50,60,70,90 |

Trapezoidal Brick | 150 | 45 | 50 | 40,50,60,70,90 |

Half Rectangular Brick | 75 | 50 | 50 | 40,50,60,70,90 |

Half Trapezoidal Brick | 75 | 45 | 50 | 40,50,60,70,90 |

Flake Brick | 150 | 25 | 25 | 40,50,60,70,90 |

Product feature details:

Good wear-resistance, heat-resistance & corrosion resistance

Alumina content of 92%, high purity, few pollution for grinding materials

Appropriate density, 3.65 g/cm3, only half of steel, making installation more convenient; Low wear loss with longer service lifer, reduce the costs of changing lining.

Why choose us?

Customized service: Match suitable sizes and quantity of bricks according to the ball mill size, bricks for feeding inlet and outlet can be customized.

Installation service: Over 30 years' experience workers can support installation service.

Transport service: We have own logistics company, provide favorable, safer & faster shipping service to you.

Packing:

Packing:

Package Details | Type | carton with pallet |

Pallet size | 1m x 1m x 0.1m (pallet size) | |

Weight | 1000-1300kg per pallet 25-27 tons load in 1X 20'FCL 20 packages/20'FCL | |

Delivery time | Usually within two weeks after confirm the order. | |

Processing:

How to install 92% alumina lining bricks?

How to install 92% alumina lining bricks?

Before installing, remove all the remaining pieces of the previously installed bricks and cement from the internal surface of ball mill. Roughen smooth surface and fix damaged iron shell with electric welding tool.

The installation gap should be within 1mm, using 425# white cement and 107# glue as combining glue.

Installation begins from side walls. Side wall will be installed with rectangle bricks totally. Then come to the cylinder installation. Use rectangle bricks and ladder type bricks in pairs. One rectangle brick following with one ladder type brick to ensure the bricks stick to the inner wall of ball mill closely. Until the last bit, if the regular size of bricks can not be fit in, use thin blocks. After finishing installation, clean up the surface.

To ensure the cement perform the maximum cohesion and intensity, spry water on the surface in the first two days. Then fill up the ball mill with water for 10 days.

We have confidence in a main land the place ample sustainable energy enhances strong communes and breeds mutual success. cheap price 92% Alumina Bricks manufacturer, The product will supply to all over the world, such as: Islamabad, Tajikistan, Malawi, Holland, We are pledged to environmental durability and mindful fabrication operations, providing us to make energy of perfect grade while encumbering our environmental effect.